Steam

Tug TID164 (Continued)

Click

here

for a short video of the engine in action

|

|

|

|

|

Faversham

1978

When

Lloyds Insurance built their smart new offices at Gun Wharf,

Chatham, they decided that steam tugs were not compatible

with their image and asked for them to be moved. TID 164 and

John H Amos first went to Milton Creek and then Faversham

Creek.

The TID was the right size for the creek but the paddle tug

kept slithering on the un-dredged mud to the centre of the

creek when the tide went out.

To try and control this she was tied to a small building,

but when the tide went out the rope demolished the building!

|

|

|

Falklands

War

When

the Survey Ship Endurance returned from the Falkland Islands

TID 164 joined in the welcome parade up the Medway to Chatham

Dockyard.

While moored at Bull Noze, the main entrance to the Dockyard,

the beer flowed freely on TID 164.

(Click

on photo for painting at Chatham Historic Dockyard)

Somehow

an influential officer heard about the difficulties of Faversham

Creek and issued a directive that two Royal Navy buoys should

be allocated for the use of TID 164 and John H Amos until such

time as a new Trust was formed.

That's how Chatham Historic Dockyard Trust found they had two

steam tugs as "squatters" which are at the dockyard

to the present day.

|

View

from the wheelhouse

|

|

1986

In 1986

the boiler was re-tubed and a lot of other work was done.

As a 'reward' for themselves the volunteers steamed TID 164 to a steam

rally at Helevetsluis in Holland.

One long standing problem had not been repaired. It took a long time,

if at all, to go astern. Imagine entering a lock, full of plastic

boats, with no means of stopping and being chased by a large collier

which had a living to earn.

Negotiating

a lock en route to the Dutch Steam Rally

|

|

|

In November 1999 TID164 became

a recognised vessel of Britain's historic fleet. The National

Historic Ships Committee added TID164 to their Designated

List.

|

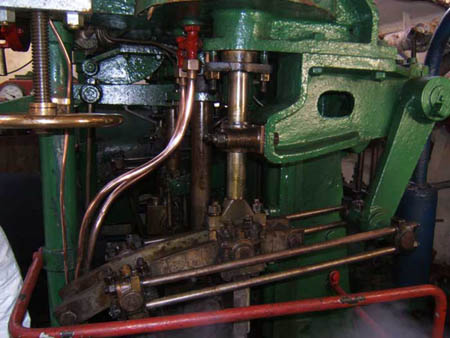

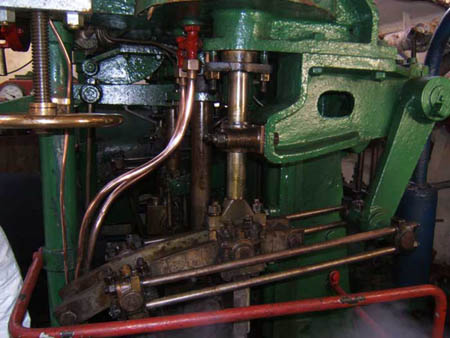

Repairs

and Rebuilds

Over

the years it is amazing how much fundamental work gets done,

and the pain of it gets forgotten: -

Re-tubing the boiler.

Re-fabricating the smoke box.

Grit blasting the hull - several times.

Continuous chipping and painting.

New funnel stays.

New steering chains.

Re-building both Weirs oil pumps.

Re-building the circulating pump.

Replacing the rudder post.

Asbestos was removed by the contractors doing the Chatham Dockyard

asbestos removal.

Installing bunker heating.

Recovering wheelhouse roof.

Civilising after cabin.

Installing diesel tank.

(When a welder was installing a diesel tank on the after deck

a spark went down a ventilator and the newly fitted-out cabin

was burnt out).

A big end bearing replaced.

|

|

|

Improvements

Continue

It was noticed that the weld along the bottom chines was failing so

two shaped steel strips were welded along the full length of the tug.

Since 1999 the cabin has been re-fitted again and the boiler has been

re-tubed again.

In 2003 central heating was installed, running pipes in cable trays

to match the original wiring and hiding radiators. This should reduce

condensation and prevent rust. Hot and cold running water may even

encourage Martin's wife to come on board!

A new fresh water tank has been installed next to the sanitary tank

forward of the wheelhouse. This has been made of wood and resin because

a steel tank would have meant the compass would have to be re-swung

- and that would cost £200!

A woodstove was installed in each cabin.

|

|

|

2004

The work continued, this time in Rod Bryant's dry dock at Otterham

Quay.

All the valves which were attached to the hull were removed,

grit blasted, re-machined and new tops fabricated where necessary,

new studs and nuts fitted and the insides coated with a modern

anti-corrosive paint.

A programme of steam pipe replacement continues.

The wood of the rubbing strake was removed, the damaged metal

cut away and renewed, and the lower metal strake replaced by

individual brackets for each bolt to prevent water retention.

The

'new' wood is 150 year old pine treated by Osmose Protim Solignum

which gives a guarantee against rot for 25 years.

|

The hull

was high-pressure water blasted and ultrasonic thickness tested. Where

plates were thin an area was cut away and patches welded flush into

the hull (not doublers), and the whole area finished with airless

sprayed red oxide and gloss paint. The tug received its regular boiler

and general surveys and was ready for steaming again.

TID 164

is currently berthed at The Chatham Historic Dockyard on the River

Medway. There is a group of volunteers on board every Saturday, who

are always happy to show interested visitors around the tug.

|

|

|

|

|

| |